Low & Medium Density Cartridge Heaters

- Product Info

- Applications

- Ordering Information

- Technical Specification

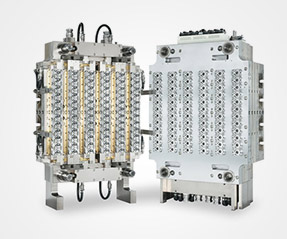

Anupam Electroheat’s Low & Medium Density Cartridge Heater is developed for heating applications not requiring high watt densities and sheath temperatures not exceeding 300°C. These Cartridge Heating Elements are designed in maximum watt densities of 30 to 45 watts per square inch depending on applications. Such a Cartridge Heating Elements of various sheath diameters can be used in any assembly, equipment or machine.

The Low & Medium Density Cartridge Heater can be absolutely customized to suit customer’s needs. Such Cartridge Heating Elements can be an economical option for customers not requiring high process temperatures. Cartridge Heating Elements are designed & calibrated perfectly to ensure that optimum conductivity between the resistance coil and the Cartridge Heater is achieved.

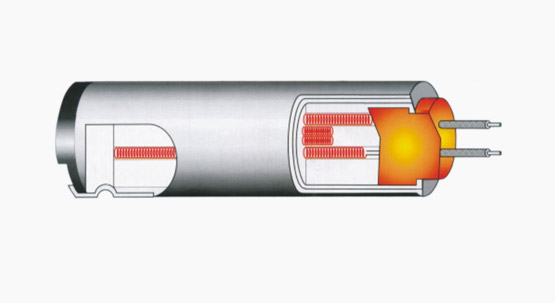

Construction

The Low & Medium Density Cartridge Heater design consists of a helically wound resistance coil made from nickel-chrome wire, evenly stretched and strung through holes in a round ceramic insulator. The element assembly is inserted into a Chrome Nickel Steel. This alloy provides the best combination of physical strength and resistance to heat oxidation up to 450°C.

Specially selected grain size and high purity magnesium oxide is used to fill all remaining space inside the ceramic insulator to increase thermal conductivity, dielectric strength, and provide longer operating life of the Cartridge Heater.

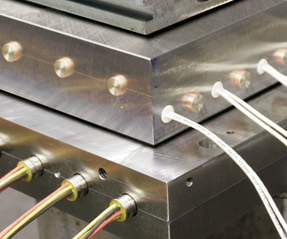

Die Platen Heating

Die Casting Industry

Extrusion Line

Hot Melt Adhesives

Packaging Industry

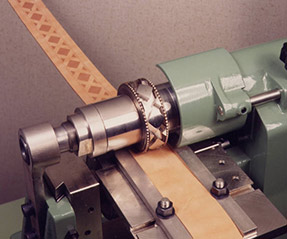

Paper Industry - Embossing Rollers

Preform Molds

Rubber Molding Industry

Seal Bars

Semi Conductor Industry

Textile Industry - Heating of Cutting Knives

- 10.00 mm

- 12.50 mm

- 16.00 mm

- 20.00 mm

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 10.00 mm | 50 | 50 | ||||

| 75 |

100 | |||||

| 100 |

120 | |||||

| 125 | 150 | |||||

| 150 | 180 | |||||

| 175 | 200 | |||||

| 200 | 250 | |||||

| 225 | 275 | |||||

| 250 | 300 | |||||

| 275 | 330 | |||||

| 300 | 360 | |||||

| 325 | 400 | |||||

| 350 | 420 | |||||

| 375 | 450 | |||||

| 400 | 480 | |||||

| 425 | 500 | |||||

| 450 | 550 | |||||

| 475 | 570 | |||||

| 500 | 600 | |||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 12.50 mm | 50 | 80 | ||||

| 75 |

120 | |||||

| 100 |

150 | |||||

| 125 | 200 | |||||

| 150 | 250 | |||||

| 175 | 280 | |||||

| 200 | 320 | |||||

| 225 | 350 | |||||

| 250 | 350 | |||||

| 275 | 450 | |||||

| 300 | 480 | |||||

| 325 | 520 | |||||

| 350 | 550 | |||||

| 375 | 600 | |||||

| 400 | 640 | |||||

| 425 | 680 | |||||

| 450 | 720 | |||||

| 475 | 750 | |||||

| 500 | 800 | |||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 16.00 mm | 50 | 100 | ||||

| 75 |

150 | |||||

| 100 |

200 | |||||

| 125 | 250 | |||||

| 150 | 300 | |||||

| 175 | 350 | |||||

| 200 | 400 | |||||

| 225 | 450 | |||||

| 250 | 500 | |||||

| 275 | 550 | |||||

| 300 | 600 | |||||

| 325 | 650 | |||||

| 350 | 700 | |||||

| 375 | 750 | |||||

| 400 | 800 | |||||

| 425 | 850 | |||||

| 450 | 900 | |||||

| 475 | 950 | |||||

| 500 | 1000 | |||||

| Diameter | Length (MM) | Recommended Watts (W) | ||||

| 20.00 mm | 50 | 120 | ||||

| 75 |

180 | |||||

| 100 |

250 | |||||

| 125 | 300 | |||||

| 150 | 375 | |||||

| 175 | 425 | |||||

| 200 | 475 | |||||

| 225 | 550 | |||||

| 250 | 600 | |||||

| 275 | 660 | |||||

| 300 | 725 | |||||

| 325 | 800 | |||||

| 350 | 850 | |||||

| 375 | 900 | |||||

| 400 | 960 | |||||

| 425 | 1050 | |||||

| 450 | 1100 | |||||

| 475 | 1150 | |||||

| 500 | 1200 | |||||

- 3/8 inch

- 1/2 inch

- 5/8 inch

- 3/4 inch

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 3/8" | 2 | 50 | ||||

| 3 |

100 | |||||

| 4 |

120 | |||||

| 5 | 150 | |||||

| 6 | 180 | |||||

| 7 | 200 | |||||

| 8 | 250 | |||||

| 9 | 275 | |||||

| 10 | 300 | |||||

| 11 | 330 | |||||

| 12 | 360 | |||||

| 13 | 400 | |||||

| 14 | 420 | |||||

| 15 | 450 | |||||

| 16 | 480 | |||||

| 17 | 500 | |||||

| 18 | 550 | |||||

| 19 | 570 | |||||

| 20 | 600 | |||||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 1/2" | 2 | 80 | ||||

| 3 |

120 | |||||

| 4 |

150 | |||||

| 5 | 200 | |||||

| 6 | 250 | |||||

| 7 | 280 | |||||

| 8 | 320 | |||||

| 9 | 350 | |||||

| 10 | 350 | |||||

| 11 | 450 | |||||

| 12 | 480 | |||||

| 13 | 520 | |||||

| 14 | 550 | |||||

| 15 | 600 | |||||

| 16 | 640 | |||||

| 17 | 680 | |||||

| 18 | 720 | |||||

| 19 | 750 | |||||

| 20 | 800 | |||||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 5/8" | 2 | 100 | ||||

| 3 |

150 | |||||

| 4 |

200 | |||||

| 5 | 250 | |||||

| 6 | 300 | |||||

| 7 | 350 | |||||

| 8 | 400 | |||||

| 9 | 450 | |||||

| 10 | 500 | |||||

| 11 | 550 | |||||

| 12 | 600 | |||||

| 13 | 650 | |||||

| 14 | 700 | |||||

| 15 | 750 | |||||

| 16 | 800 | |||||

| 17 | 850 | |||||

| 18 | 900 | |||||

| 19 | 950 | |||||

| 20 | 1000 | |||||

| Diameter | Length (inch) | Recommended Watts (W) | ||||

| 3/4" | 2 | 120 | ||||

| 3 |

180 | |||||

| 4 |

250 | |||||

| 5 | 300 | |||||

| 6 | 375 | |||||

| 7 | 425 | |||||

| 8 | 475 | |||||

| 9 | 550 | |||||

| 10 | 600 | |||||

| 11 | 660 | |||||

| 12 | 725 | |||||

| 13 | 800 | |||||

| 14 | 850 | |||||

| 15 | 900 | |||||

| 16 | 960 | |||||

| 17 | 1050 | |||||

| 18 | 1100 | |||||

| 19 | 1150 | |||||

| 20 | 1200 | |||||

*More sizes available on request

| Feature | Low Density Cartridge Heater | Medium Density Cartridge Heater | ||||

| Max. Surface Load | 4 w/cm² | 12 w/cm² | ||||

| Wattage Tolerance |

±10% | ±10% | ||||

| Insulation Resistance |

≥ 5 MΩ at 500V (DC) | ≥ 5 MΩ at 500V (DC) | ||||

| Standard Dia Range |

8mm to 40mm | 8mm to 20mm | ||||

| Diameter Tolerance | - 0.1mm | - 0.1mm | ||||

| Standard Length | Minimum 50mm | Minimum 50mm | ||||

| Length Tolerance | ± 1.5%, min ± 2mm | ± 1.5%, min ± 2mm | ||||

| Max. Sheath Temperature | 400° C | 650° C | ||||